© SATRA Technology Centre. Reproduction is not permitted in any form without prior written permission from SATRA.

Genuine leather or lookalike material?

Explaining some of the key differences between real leather and leather-like materials.

For anyone entering the leather product supply chain, one of the most difficult things can be trying to establish if the item being considered is made from genuine leather or from a material that has been produced to imitate leather in some way. This article will look at some of the ‘clues’ to help differentiate between leather and ‘lookalike’ materials.

What is leather?

Before looking at other materials and constructions that imitate leather, it is worth reminding ourselves of the definition of leather. It is worth considering how leather is defined, as the amount of finish applied plays an important role in the definition. Globally, there are a number of documents that define the term ‘leather’. The wording is subtly different, but the intention is the same. A definition of leather is to be found in the British Standard BS 2780:1983+A1:2013 – ‘Glossary of leather terms’, as well as the International Council of Tanners (ICT) ‘International glossary of leather terms’, and in European standard EN 15987:2022 – ‘Leather – Terminology – Key definitions for the leather trade’. There is also an International Standards Organisation (ISO) glossary of leather terms, ISO 15115:2019 – ‘Leather – Vocabulary’.

The widely-used BS 2780 defines leather as: ‘Hide or skin with its original fibrous structure more or less intact, tanned to be imputrescible. The hair or wool may, or may not, have been removed. Leather is also made from a hide or skin which has been split into layers or segmented, either before or after tanning’.

The definition also includes the qualifying notes:

NOTE 1 If the leather has a surface coating, the mean thickness of this surface layer, however applied, must be 0.15 mm or less.

NOTE 2 If the tanned hide or skin is disintegrated mechanically and/or chemically into fibrous particles, small pieces or powders and then, with or without combination of a binding agent, is made into sheets or other forms, such sheets or forms are not leather.

NOTE 3 The term ‘leather’ should not be used in conjunction with any word to describe a product or material if the product or material does not conform to the definition of leather.

Identification techniques

The most commonly used technique for identifying if a material is genuine leather or an alternative material is to use microscopy. A light microscope is sufficient to establish images with a high enough resolution for most identification purposes.

However, it is also possible to use a scanning electron microscope to carry out more detailed identification at the fibril level (leather fibre bundles that are visible to the eye are made up from collagen fibres which in turn are made from collagen fibrils). For day-to-day identification in the supply chain, though, a hand-held loupe (a magnifier – sometimes with a built-in light source) can give reliable images of the surface and, to some degree, the cross section of the material. The BS EN ISO 17131:2020 – ‘Leather. Identification of leather with microscopy’ standard can be used for verification.

Textile lookalikes

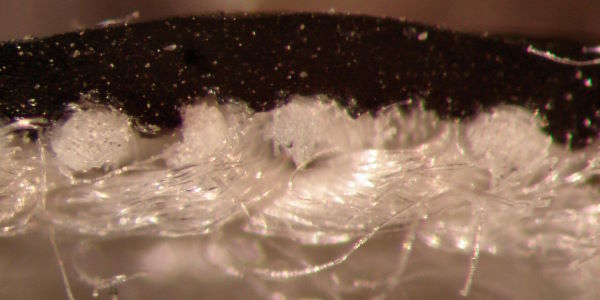

One of the key factors that points to a material not being leather is a very consistent appearance or ‘uniformity’ through the cross section. To illustrate this, the cross section of bovine leather (figure 1) shows the non-uniform nature of the collagen fibre structure through the thickness of the leather. In comparison, figures 2 and 3 show examples of typical materials designed to look like leather – a polyvinyl chloride (PVC)-coated fabric and a polyurethane (PU)-coated fabric. It is obvious from the cross section that the structure is much more consistent in appearance than that of the natural variation noticeable in leather, and the separate layers of coating and textile substrate (base material) are easily distinguished.

Figure 1: A cross section of bovine leather

Leather Wise Ltd

Figure 2: Polyvinyl chloride (PVC)-coated fabric

Leather Wise Ltd

Figure 3: Polyurethane (PU)-coated fabric

Materials using leather fibre

In an attempt to make an imitation leather more convincing, there are now textiles on the market where a layer of leather fibre has been adhered to the under surface of the textile substrate (figure 4). This can be particularly difficult to identify by eye and feel, as the PVC/PU surface can certainly look and feel like leather, and the under-surface also gives the same impression as a consequence of the leather fibre.

Leather Wise Ltd

Figure 4: A layer of leather fibre adhered to the under-surface of a textile substrate

These materials are often of a lighter weight than leather of similar thickness. However, it is important to remember that to define a material as leather it must have its original fibrous structure more or less intact and not just be manufactured from leather fibres or particles. Therefore, care must be taken to ensure that this material is not mistakenly classified as leather, due to the presence of the leather fibres on the surface.

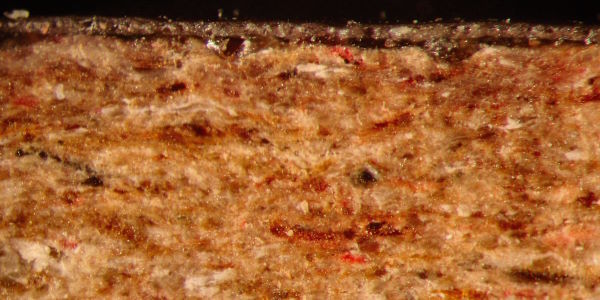

Some materials available to the product manufacturer may be based on leather fibre but do not fit the definition of leather. It is very important that the products are correctly labelled or described at the point of sale, so as not to breach consumer law. The definition most likely to be used is ‘leather fibre board’ or ‘bonded leather fibre’ (figure 5). Products made from this material may look like leather, but their physical properties and their performance will differ in use to leather, so it is essential that consumers are not misled.

Leather Wise Ltd

Figure 5: ‘Leather fibre board’ or ‘bonded leather fibre’

Leather fibre board (bonded leather fibre)

Fibre board – also called ‘bonded leather fibre’ – is a material where tanned hides or skins are disintegrated mechanically and/or chemically into fibrous particles, small pieces or powders which are then, with or without the combination of chemical binding agent, made into sheets. This contains a minimum of 50 per cent by weight of dry leather fibre. If there is any other component apart from leather fibre, binding material and leather auxiliaries, this must be declared as part of the description.

Consumer expectations

While any of the imitation leather materials discussed above are perfectly acceptable materials to use in many applications instead of leather, it is important that the user understands that the performance in use will be quite different to that of leather. In many instances, these materials do not demonstrate the same level of durability, tear resistance, flex resistance, breathability or ‘mouldability’ that are all benefits of using leather. One advantage that these materials do have, however, is the fact that they are produced on a roll or in sheets. Therefore, they can be nested and cut easily with low levels of waste.

As long as there is no intent to mislead the consumer or incorrectly describe a product as leather when it is an imitation, there is a place on the market for both leather and leather lookalikes. However, it is important that the technologist fully understands what he or she is specifying and what performance levels are realistic for that material. SATRA can assist with this if further clarification is required.

How can we help?

15 PER CENT DISCOUNT ON FIRST SATRA TEST — please click here.

Please email leather@satra.com for further information on material that has been produced to imitate leather, and its correct use in the production of footwear, bags and other goods.

EN

EN ZH

ZH