© SATRA Technology Centre. Reproduction is not permitted in any form without prior written permission from SATRA.

Requirements for chemically protective gloves

Explaining the testing required as part of the certification process for chemically protective gloves in the UK and Europe.

Image © iStock.com/Smederevac

Many modern industrial processes involve the use of highly concentrated and potentially dangerous chemicals. Information from studies into possible detrimental health effects caused by long-term or short-term exposure to chemicals is made available through the supply chain via safety data sheets. In the workplace, there is a duty of care to minimise workers’ contact with any substance that may have an adverse effect upon human health.

Working safely with these hazardous chemicals requires adherence to strict safety procedures and the use of specially-designed personal protective equipment (PPE). In terms of splashes and spills from liquid chemicals, workers’ hands can be of particular concern. Therefore, specialist gloves have been developed to protect their hands against exposure to chemicals. The level of protection against chemicals provided by a particular glove will depend not only on the construction of the glove, but also on the materials – usually the polymer(s) from which the glove is made.

These materials must provide protection against the chemicals with which the gloves are intended to be used.

The polymer or polymers used in suitable gloves protect the hand and lower arm by preventing the chemicals from coming into contact with the inside of the glove. To be effective, each material must resist the passage of the chemicals through its structure, either by direct penetration or permeation. It must also resist degradation by the chemicals that would lead to such damage as cracking or holing when the glove is flexed or stretched during use.

A European standard to assess glove performance against chemicals (EN 374-1) was first published in 1994. The current version of this standard is EN ISO 374-1:2016+A1:2018. This standard contains the terminology and performance requirements for gloves protecting against chemical risks. In this article, we provide a guide to the requirements of EN ISO 374-1:2016+A1:2018 and details of how SATRA can help with both the testing and certification of chemically protective gloves.

Penetration

The movement of a chemical through a material, seam, pinhole or other imperfection on a non-molecular level is defined as ‘penetration’ in EN ISO 374-1. All chemically protective gloves must not leak when tested in accordance with EN ISO 374-2:2019. This test method consists of two procedures – testing to determine if either air or water will penetrate the glove.

For the air leak test, the glove is immersed in water and pressurised with air. If a stream of bubbles is observed coming from the surface of the glove, this indicates that air has penetrated the glove. A similar principle is applied to the water leak test. In this assessment, the glove is filled with water and penetration is observed by the appearance of water droplets on the outside surface of the glove.

Permeation

‘Permeation’ is the process in which a chemical moves through a material at the molecular level. Testing permeation resistance is carried out in accordance with EN 16523-1:2015+A1:2018 and involves exposing the outer surface of the glove material to the challenge chemical in one section of a two-chamber test cell. The second chamber contains the collection medium (typically an inert gas or a liquid) which is connected to the detection system.

For organic solvents – for example, n-heptane or methanol – the detection system is usually a gas chromatograph with flame ionisation detection (GC-FID). For chemicals such as 40 per cent sodium hydroxide or 96 per cent sulphuric acid that are diluted in water, the detection system is typically a conductivity meter or a pH meter. Inside the test cell, the glove material acts as a barrier to separate the challenge chemical from the collecting medium.

During the test, the amount of test chemical that permeates through to the collecting medium is measured until a predetermined permeation rate is reached – 1 μg of chemical per cm2 of material per minute of the test. The time for this to occur (known as the ‘breakthrough time’) is the key data. The breakthrough time determines the material’s performance level and is defined in table 1. The challenge chemicals selected for testing will depend upon the end use of the glove and the glove type classification which the manufacturer wishes to obtain (see the section on ‘marking’ for further details).

| Table 1: Permeation performance levels | |

| Measured breakthrough time (minutes) | Permeation performance level |

| > 10 | 1 |

| > 30 | 2 |

| > 60 | 3 |

| > 120 | 4 |

| > 240 | 5 |

| > 480 | 6 |

EN ISO 374-1 contains a list of 18 challenge chemicals (see table 2), the code letters for which can be used on the glove marking. However, other chemicals and mixtures can also be tested to EN 16523-1 and the breakthrough times included in the user instructions. Three test specimens are taken from the palm area of the glove. For gloves longer than 400 mm and for gloves where the cuff is also claimed to provide protection, another three test specimens are also taken from the cuff area. If the glove contains a join or seam in the hand area, this must also be tested.

| Table 2: List of test chemicals specified in EN ISO 374-1:2016 + A1:2018 | |||

| Code letter | Chemical | CAS number | Class |

| A | Methanol | 67-56-1 | Primary alcohol |

| B | Acetone | 67-64-1 | Ketone |

| C | Acetonitrile | 75-05-8 | Nitrile compound |

| D | Dichloromethane | 75-09-2 | Chlorinated hydrocarbon |

| E | Carbon disulphide | 75-15-0 | Organic compound containing sulphur |

| F | Toluene | 108-88-3 | Aromatic hydrocarbon |

| G | Diethylamine | 109-89-7 | Amine |

| H | Tetrahydrofuran | 109-99-9 | Heterocyclic ether |

| I | Ethyl acetate | 141-78-6 | Ester |

| J | n-heptane | 142-82-5 | Saturated hydrocarbon |

| K | 40 per cent sodium hydroxide | 1310-73-2 | Inorganic base |

| L | 96 per cent sulphuric acid | 7664-93-9 | Inorganic mineral acid |

| M | 65 per cent nitric acid | 7697-37-2 | Inorganic mineral acid |

| N | 99 per cent acetic acid | 64-19-7 | Organic acid |

| O | 25 per cent ammonium hydroxide | 1336-21-6 | Inorganic base |

| P | 30 per cent hydrogen peroxide | 7722-84-1 | Peroxide |

| S | 40 per cent hydrofluoric acid | 7664-39-3 | Inorganic mineral acid |

| T | 37 per cent formaldehyde | 50-00-0 | Aldehyde |

The reported test results are based upon the lowest breakthrough time achieved by any of the triplicate test specimens. There are six permeation performance levels, with level 6 being the highest level of protection, signifying a breakthrough time of greater than 480 minutes (see table 1).

Degradation

Degradation is defined in EN ISO 374-1 as ‘a deleterious change in one or more properties of a material due to contact with a chemical’. Indications that degradation has occurred include flaking, swelling, disintegration, embrittlement, discolouration, a change in appearance and hardening or softening. In theory, a material could have an excellent resistance to chemical permeation but, as the EN 16523-1 test method to assess permeation requires the material to be motionless during the testing, it may perform poorly in ‘real-life’ situations if exposed to a chemical that degrades the material. For instance, if a glove material were to harden or become brittle when exposed to a chemical in use, the dextrous nature of the glove would be compromised, and so could the protection provided by this glove to a wearer.

Testing is carried out in accordance with EN ISO 374-4:2019. The principle of the test is to measure if there is a change in the force required to puncture the glove material after continuous contact of its external surface with a challenge chemical. The force required to succeed in pushing a standard stylus through a specimen of the glove material is compared before and after exposure to the challenge chemical.

Although EN ISO 374-1 contains no degradation performance requirements, for chemicals referenced in the glove marking, the EN ISO 374-4 result must be included in the user instructions to make this information available to the end user.

The test result is reported as a percentage degradation, so values could be positive (if the material has become softer and less force is required to puncture it after chemical exposure) or negative (if the material has become harder and the force required has increased after chemical exposure). If a protective glove is longer than 400 mm in length, meaning that permeation testing has been conducted on both the cuff and the palm, degradation testing must at least be carried out for the area which achieved the lowest permeation result.

Protection against microorganisms

Many chemically protective gloves are also intended to provide the wearer with protection against harmful microorganisms. These products must also comply with the requirements of EN ISO 374-5:2016. For gloves claiming protection against bacteria and fungi only, there must be no air or water leaks when testing for penetration in accordance with EN ISO 374-2.

If protection against viruses is also claimed, an additional test – ISO 16604:2004 – is required. This is intended to address the risk of very small virus particles passing through the gloves. The test involves exposing the external surface of the gloves to a suspension of virus particles under a specific hydrostatic pressure, and determining whether there is penetration through to the internal surface. If penetration does not occur, the gloves pass the test and protection against viruses may be claimed. Testing in accordance with ISO 16604 is not mandatory for all chemically protective gloves, and this will only be required if protection against viruses is claimed.

Marking of chemically protective gloves

Figure 1: Flask pictograms for type A, B and C gloves, showing tested chemicals identified by their code letters

The marking of chemically protective gloves (see figure 1) must be in accordance with the general requirements for protective gloves in the current version of EN ISO 21420 and the specific requirements stated in EN ISO 374-1.

There are three classification types of chemically protective gloves, depending on their permeation test results. ‘Type A’ gloves have achieved a performance level 2 or greater against at least six of the chemicals listed in EN ISO 374-1 (see table 2). ‘Type B’ gloves have achieved level 2 or greater against at least three of the chemicals listed in EN ISO 374-1. ‘Type C’ gloves have achieved at least level 1 against at least one of the chemicals listed in EN ISO 374-1.

Reference to the EN ISO 374-1 standard must be given for each of the three categories, as well as listing the glove type. The chemicals against which protection is claimed are identified by their code letter under the flask pictogram. If the manufacturer wishes to claim permeation resistance against chemicals not listed in EN ISO 374-1, this information can be detailed in the user instructions provided with the product.

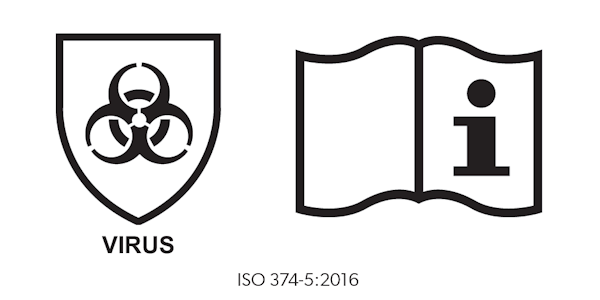

Gloves claiming protection against microbiological risks must also bear the pictogram shown in figure 2, with reference to the EN ISO 374-5 standard. If the optional protection against viruses is not claimed for the product, the word ‘VIRUS’ must not be present below the symbol.

Figure 2: Marking of gloves protecting against viruses, bacteria and fungi

User instructions

User instructions in accordance with the requirements given in EN ISO 21420 must be supplied by the manufacturer. In addition, chemical glove user instructions are to include the results of penetration, degradation and permeation testing. There should be a list of all the chemicals against which the gloves have been tested, in addition to the performance levels for permeation testing.

There are also several specific warnings that should be highlighted, including drawing the user’s attention to the fact that the level of chemical resistance may be different if the chemical is used in a mixture. If the gloves are intended to be reused, instructions must be provided for decontamination. If no information is given regarding decontamination, it must be stated in the user information that the glove is for single-use only. These specific requirements for chemically protective gloves are stated in clause 7 of EN ISO 374-1.

CE and UKCA certification

Gloves which are intended to protect the wearer against risks that may cause very serious consequences, such as irreversible damage to the wearer’s health, are classified as ‘Category III’ PPE. Chemically protective gloves fall into this category. To place the product on the market within the European Union (EU), the gloves must be CE-marked. A Notified Body is required to assess a manufacturer’s technical documentation and to check the conformity of ongoing production control against the PPE Regulation (Regulation (EU) 2016/425). Involvement of an Approved Body is required if the gloves are to be UKCA-marked for the UK market only.

How can we help?

15 PER CENT DISCOUNT ON FIRST SATRA TEST — please click here.

SATRA can help glove manufacturers with testing, CE and UKCA certification services. Please contact ppe@satra.com for further details.

EN

EN ZH

ZH